Our Makers

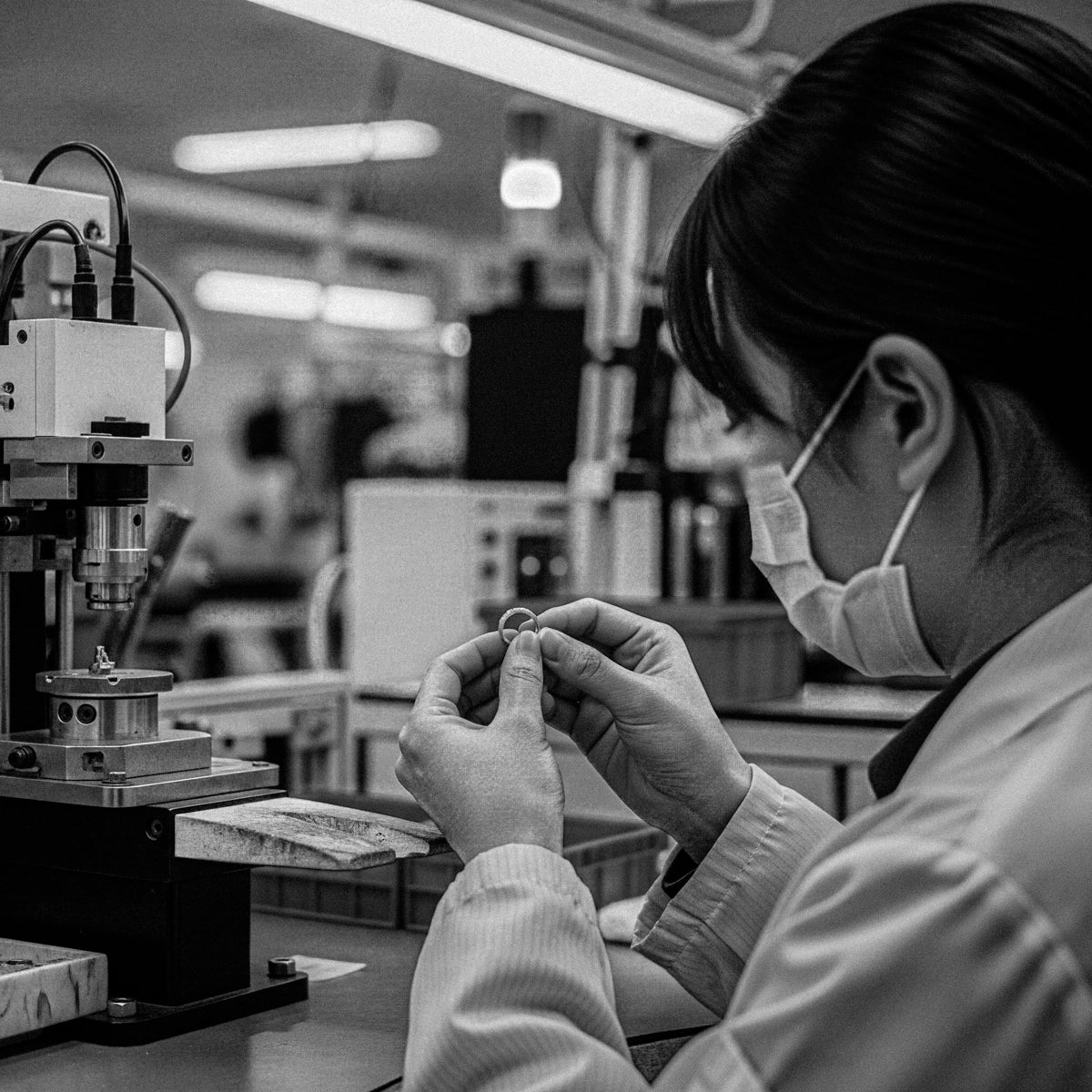

Behind every piece are people whose care and skill bring it to life. We choose to work with a partner who shares our values, where people are treated with dignity, quality is honoured, and the environment is respected. Certified by the Responsible Jewellery Council (RJC), they ensure every step of the journey, from traceable raw materials to the finished piece, upholds responsible practices and protects both people and planet.

Their workplaces are fair, safe, and supportive, recognised by Intertek, a globally recognised organisation that reviews working conditions, safety, and wellbeing. This commitment includes empowering women and minorities, supporting parents through flexible working arrangements, providing fair wages that allow makers to live with stability and respect, and offering opportunities for everyone to develop new skills and grow in their roles.

Conscious Craftsmanship

Care for the environment is considered in every process. Energy is used thoughtfully, waste is carefully minimised, and resources are managed with care. These practices are continually refined to reduce impact, which is reflected in ISO 14001 certification. Alongside this, ISO 9001 certification helps ensure every stage of production is consistent, precise, and carried out with care.

Recycled metals are used wherever possible, and processes are designed to reduce environmental impact without compromising quality. Each piece carries the result of thoughtful craftsmanship and mindful choices, with every detail reflecting the care of the hands that made it and a deep respect for the world around us.

Our Plating Process

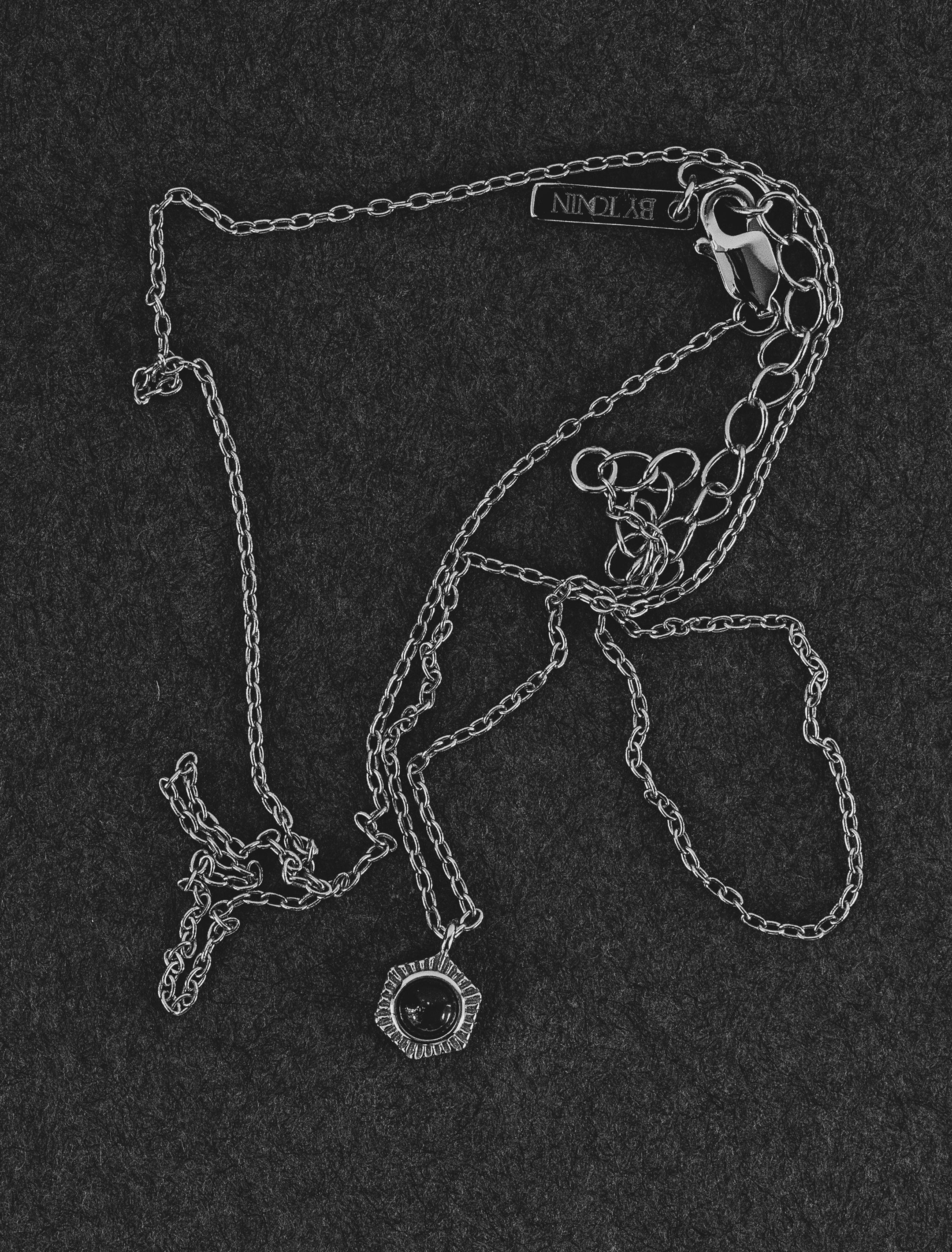

Up to four times thicker than common industry plating, our method begins with recycled sterling silver and two layers of silver plating to create a smooth, durable foundation.

A protective layer of palladium is then added to help guard against tarnishing and support long-term wear.

Over this, we apply 18k gold, at least 1 micron thick for our standard pieces, and a minimum of 2.5 microns for gold vermeil, giving each piece its warm, signature glow.

Finally, an innovative nano-ceramic e-coating seals the finish, adding further resistance to everyday elements.

A refined process for a flawless finish.

Quality Testing

Each batch moves through a considered testing process to ensure it meets our standards of quality.

Chemical resistance is assessed through salt-spray and sulfur-dioxide exposure, simulating everyday contact with moisture and pollution. Abrasion testing follows, replicating the gentle friction of daily wear.

The pieces are then placed under high heat and humidity to confirm their stability in more demanding conditions. Transport testing ensures they remain protected throughout their journey to you.

Every batch is supported by detailed reports verifying the integrity of both materials and plating. Thickness is measured at three points on each piece to ensure an even, consistent finish.

Before packing, each piece is carefully hand-inspected, so you receive jewellery we’re truly proud to share.

Our Craft and Commitment

Sustainable, Ethical Jewellery

Sustainable Practices, Premium Craftsmanship, Proven Quality

At BY TONIN, we partner exclusively with Responsible Jewellery Council (RJC) and ISO 9001 certified manufacturers to ensure the highest standards in ethical sourcing, sustainable production, and precision quality control. Every piece is crafted using a multi-layer plating process—featuring a sterling silver base, palladium anti-tarnish layer, and thick 18k gold, sealed with a nano-ceramic coating for enhanced durability and shine.

Each design undergoes rigorous quality testing, including chemical, abrasion, heat, and transit simulations, with detailed batch reporting and careful hand inspection. The result: responsibly made jewellery designed to last—crafted with integrity, and made to be worn every day.